- Home

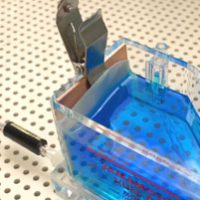

- Brush Plating, Technique

- Equipment required for brush plating and how to select it

TECHNICAL INFORMATION

Equipment required for brush plating and how to select it

If you have an overview of brush plating but are not sure how to choose the right product, here is how to select our brush plating products.

If you would like to know more about the outline of brush plating, please click the link below first.

In selecting the equipment needed for brush plating, the following conditions must be determined.

- Material and area to be plated

- Type of plating

1. Choose a brush tool

Brush tools by area to be plated

As a guide, for an area of 30 mm square or less, use the FS-1 brush type, SS-1(platinum tip) suitable for precious metals, or the SS-3 (carbon φ3mm) ;

for 31 to 100 mm square, use the carbon SS-5 or SS-10;

and for 101 mm square or more, use the carbon K-A, K-B, or SS-20.

| Plating Area | Product No. | Tip Material | Product Picture |

|---|---|---|---|

| ~30(㎜) square | A-43-FS-1A | Brush | |

| A-43-SS-1A | Platinum | ||

| A-43-SS-3A | Carbon Nickel | ||

| 31~100(㎜)square | A-43-SS-5 | Carbon Nickel Copper | |

| A-43-S-10 | Carbon Nickel Copper | ||

| 101~(㎜)square | A-43-K-A | Carbon |   |

| A-43-K-B | Carbon |   |

|

| A-43-K-L | Copper Nickel Tin Zing | ||

| A-43-S-20 | Carbon |

How to select materials

Choose a platinum brush tip for precious metals and a carbon brush tip for other materials. For nickel or copper plating, a brush tip made of the same material is better, but carbon is also fine.

Number of brush tools

The same number of brushes as the type of solution is necessary to prevent the solutions from mixing.

For instance, for nickel plating, one brush for electrolytic degreasing, one for activation, and one each for strike nickel and nickel, for a total of 4 brushes.

For no-cyanide silver, two brushes are required, one for strike and one for no-cyanide silver, since this solution and solution A are mixed together when used.

2.Select a power supply

Two types of power supplies are available for brush plating.

Choose B-67 if the area to be plated is less than 100 mm square, and choose B-63 if the area is 101 mm square or more.

3.Select a degreasing solution

There are two types of electrolytic degreasing solution. Please use the one for general use except for aluminum plating.

Electrolytic degreasing is a method of degreasing plated materials in an alkaline solution by alternately changing the cathode or anode or polarity. The force of gas generation removes the stains that have solidified and adhered to the surface of the plated material. Insufficient degreasing is an important process that can cause poor adhesion of the plating, so it must be performed.

| General use | Aluminium Material |

|---|---|

| Electrolytic Degreasing Solution (1)(for general use) (BP-ELC-01) | Electrolytic Degreasing Solution (for Aluminium) (BP-ELC-02) |

4.Select an Activating Solution

Select the activator based on the material to be plated.

Use Activating Solution (1) for chrome and stainless steel.

Use Activating Solution (2) for iron, copper and copper alloys material.

For carbon steel, use both Activate (3) and Activate (4), and for aluminum, use both Activate (6-1) and Activate (6-2).

Activation is a method of immersing the plated material in an acid solution to remove the remaining thin oxide film, which is important for good adhesion of the plating.

| Chrome and stainless steel | Iron, copper and copper alloys Material | Carbon steel | Aluminum Material |

|---|---|---|---|

| Activating Solution (1) (BP-ACT-01) | Activating Solution (2) (BP-ACT-02) | Activating Solution (3) (BP-ACT-C) | Activating Solution (6-1) (BP-ACT-AL-1) |

| Activating Solution (4) (BP-ACT-04) | Activating Solution (6-2) (BP-ACT-AL-2) |

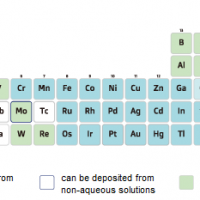

5.Select your plating solution

Depending on what you want to plate, we offer more than 20 different plating solutions.

Brush plating solutions are thicker than normal plating solutions and should be used exclusively.

| Non-cyanide Gold☆ (BP-AU-02) | Copper (acidic) (BP-CU-01) | Nickel (acidic) (BP-NI-01) |

| Non-cyanide Silver☆ (BP-AG-03) | Copper (alkaline) (BP-CU-02) | Strike Nickel (BP-NI-04) |

| Palladium☆ (BP-PD-02) | Thick Copper (acidic) (BP-CU-03) | Nickel (neutral) (BP-NI-06) |

| Platinum☆ (BP-PT-01) | Copper (neutral) (BP-CU-04) | Tin(alkaline) (BP-SN-01) |

| Rhodium☆ (BP-RH-01) | Zinc (acidic) (BP-ZN-02) | Tin(acidic) (BP-SN-02) |

| Nickel Tungsten (BP-NIW-01) | Nickel Cobalt (Hexavalent Chromium Color ) (BP-CR-02) | Strike Nickel (for Aluminium) (BP-NI-09) |

| Cobalt (BP-CO-01) | Black Nickel (alkaline) (BP-NI-05) |

Frequently asked questions about “whether brush plating is acceptable for each type of plating”, “how to use it”, and ” how to purchase it ” are summarized the link below. If you have any questions, please check the FAQ before contacting us.

Frequently asked questions about brush plating