- Home

- Hull Cell, Technique

- What is Hull Cell Test?

TECHNICAL INFORMATION

What is Hull Cell Test?

We have been selling Hull Cells, one of our most beloved items, for a long time.

In this section, we would like to introduce basic theory of Hull Cell and how to use it briefly.

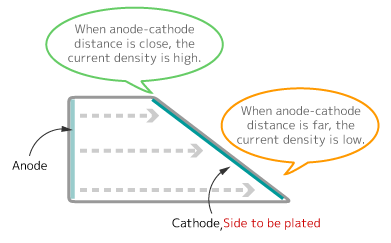

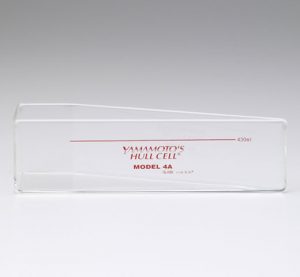

Hull Cell is a tank for test of plating, invented by Dr. R. O. Hull. By using trapezoidal shaped cell, it became possible to observe state of deposition under current density with continuous wide range. It also becomes easier to observe relationship between current density and state of deposition by changing plating conditions.

By creating a difference of distance between the anode and cathode, deposited film of a wide range of current densities (from high to low, far exceeding the range applied in normal use) can be observed on a single test-piece.

What can I know from Hull Cell test?

In actual plating scene, it is extremely important to know the condition of plating bath to control quality of final products.

However, plating bath is being changed always alongside the plating processes. Therefore plating bath always has to be tested from variety of perspectives.

Test methods for plating bath are able to be divided into 2 : quantitative analysis such as chemical analysis or physical chemical analysis (e.g. pH, specific gravity, and so forth) and qualitative analysis such as deposition examination like Hull Cell test or Haring Cell test.

Among these test methods, Hull Cell test’s feature is that Hull Cell test performs actual plating. So observer can see actual plating sample and check state of the brightness, covering of the plating film to know condition of plating bath.

Additionally, by making standard sample of the plating in advance, it becomes possible to predict future trouble of bath and prevent it before happening.

What should I do to perform the test?

To perform the test, needs to determine test condition based on the type of plating bath to be tested. Below is examples of test conditions. Since heating / agitation conditions can be changed based on type of plating bath, we sell a variety of Hull Cells. Please check a table below to find the Hull Cell suitable for your plating conditions.

| Plating solution | Cathode | Anode | Total current (A) | Duration (min.) | Temperature (℃) | Agitation | Note |

|---|---|---|---|---|---|---|---|

| Copper cyanide | Iron | Oxygen-free Copper (Electrolytic Copper) | 2 | 5 - 10 | 20 - 60 | None / air bubbling | PR may be used. |

| Copper sulfate | Brass | Phosphorous copper/Iridium plated titanium | 2 - 3 | 5 - 10 | R.T - 30 | Air bubbling | |

| Copper pyrophosphate | Brass / Iron | Oxygen-free Copper (Electrolytic Copper) | 2 | 5 | 50 - 60 | Air bubbling | |

| Nickel | Brass | Electrolytic Nickel (pure nickel) | 2 - 3 | 5 - 10 | 40 - 60 | None | |

| Nickel | Brass | Electrolytic Nickel (pure nickel) | 0.5 - 1 | 5 | 40 - 60 | Air bubbling | To judge existence of metal impurities |

| Nickel sulfamate | Brass | SK nickel(nickel contains sulfur) | 0.5 - 1 | 5 | 40 - 60 | Air bubbling | |

| Chromium | Brass | 5% Tin-contained Lead | 5 | 3 | 40 - 50 | None | To judge contamination of chloride by inspecting back side. |

| Chromium | Nickel-plated brass | 5% Tin-contained Lead | 10 | 1 | 40 - 50 | None | |

| Zinc chloride | Iron | Zinc | 2 | 5 | R.T. | None | |

| Acid tin | Iron / Copper | Tin | 2 | 5 | 18 - 20 | Cathode rocking(mechanical agitation) |

List of Hull Cells

| Product name | Product No. | Appearance | Features |

|---|---|---|---|

| Hull Cell (Thermostatic-Control-type Tank) | B-53/B-53W |  | Warming up by heater and air agitation are available. |

| Hull Cell (Air-Agitation-type Tank) | B-54W |  | Air agitation is available. |

| Diaphragm-type Hull Cell(Air-Agitation-type Tank) | B-54-DW |  | To prevent from consumption of additives if used with insoluble anodes such iridium oxide or iridium coated titanium. Mainly for copper sulfate bath. |

| Hull Cell (Standard-type Tank) | B-55 |  | Standard type. Mainly for solder, tin plating. |

| Hull Cell (Standard/Glass-type Tank) | B-55-G |  | Same shape with B-55 but made of glass. Possible to be indirectly warmed up by using water bath. |

| Smart Hull Cell | B-53-SM/B-53-SMW |  | Not only warming up by heater and air agitation, but also overflow agitation is available. Suitable for plating condition which can not use air agitation. Volume is 500ml and suitable for composite plating. |

| Hull Cell (for Chromium-Use Tank) | B-56 |  | For hexavalent chromium plating. To prevent from intense rise of temperature, a Hull Cell with holes is set inside 1L tank. Made of PVC. |

| Hull Cell (Thermostatic-Control-Type/Long Tank) | B-53-L/B-53-LW |  | Long type such as B-55-L. Warming up by heater and air agitation are available. |

| Hull Cell (Air-Agitation/Long-type Tank) | B-54-L/B-54-LW |  | Long type such as B-55-L. Air agitation is available. |

| Hull Cell (Standard/Long-type Tank) | B-55-L |  | Cathode side is longer than standard Hull Cell so that difference come from current density can be observed more in detail. Suitable for alloy plating. |

| Hull Cell (Standard-Type, Glass Long-type Tank) | B-55-LG |  | Long type such as B-55-L. Made of glass. |

| Tenori Hull Cell (Air-Agitation-type Tank) | B-54-HW |  | Small size such as B-55-H. Air agitation is available. Mainly for precious metal plating. |

| Tenori Hull Cell (Standard-type Tank) | B-55-H |  | Possible to perform Hull Cell test with one eighth liquid volume (33ml) compared with standard Hull Cell. Mainly for precious metal plating. |

| Tenori Hull Cell (Standard/Glass-type Tank) | B-55-HG |  | Small size such as B-55-H. Made of glass. Mainly for precious metal plating. |

For those who unclear which Hull Cell is suitable, a set product contains all of basic equipment is also available.

4. Performing Hull Cell test

To perform actual Hull Cell test, please refer to procedure below.

4-1. Confirm conditions such as type of anode, type of cathode, bath temperature, type of agitation, and so forth. Then install equipment.

4-2. Perform pre-treatment of plating sample (cathode)

Note: We sell many types of metallic cathode plate, and many of them are protected with semi-transparent or blue film on a side of plate. Before performing test, please peel off the film, and use the side which used to be covered with the film. In some cases, adhesive from the film may be remaining on the plate, so please perform pre-treatment well.

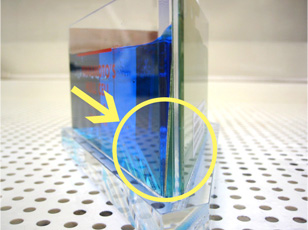

4-3. Confirm if anode and cathode are correctly set.

Cathode (plating sample) often be set improperly (diagonally), like a photo below. Please make sure that cathode is properly set, as a wall of Hull Cell tank and a cathode plate stick together.

Example of Hull Cell test

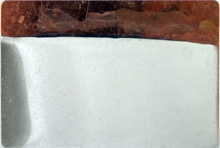

5. Evaluation of test result

After plating is done, you can obtain test piece in the status like below. The photos below are test results of bright tin plating. The left side of photo is high-current part since anode is closer, and the right side is low-current part. Dark gray part on the left is so-called “burnt” part. The condition of plating film is like “burnt”, so this part can not be used for actual products. Compared with upper photo (standard bath), lower photo (bath with less brightener) shows difference such as brightness condition and no plating film on the low-current part.

High <― Curent Density ―> Low

However, in case pre-treatment of cathode plate is not done properly, “no deposition” on the low-current part, and/or pits on plating film can be happen. In that case, it becomes unclear that which is the reason of “no deposition”, insufficient pre-treatment or improper bath composition? Therefore, pre-treatment must be performed enough.

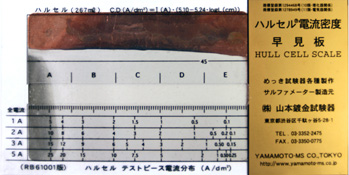

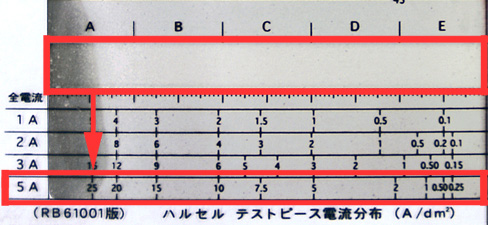

Current density distribution on the plating sample changes depend on total current. Condition of distribution can be observed easily by using “B-61 Hull Cell Scale”.

For example, photo above is a test piece performed with total current “5A”. So the part up to 1cm from the left side is ” 25A/dm2 “. And that means in this test condition, if current density exceeds 25A/dm2 , its plating film will be burnt. Appearance changed depending on observed position, so please use opening of the scale to observe the same position every time.

Additionally, the Hull Cell Scale was calculated with formula below based on R. O. Hull formula and German standard (DIN 50957-1 )*1

C.D =I・(5.10-5.24・logL)

C.D:Current Density (A/dm2)

I:Total Current(A)

L:Distance from the edge of high current side on cathode plate (cm)

If you have any other questions regarding Hull Cell test, please feel free to contact us.

|

Mr. Harry Hull and our President (at SURFIN2017)Harry, the son of Dr. R.O.Hull, praised the quality of our Hull cell as “the world’s best” and was pleased with the technology diffusion and long-term sales of Hull Cell. |