TECHNICAL INFORMATION

Overview of Barrel Plating Equipment

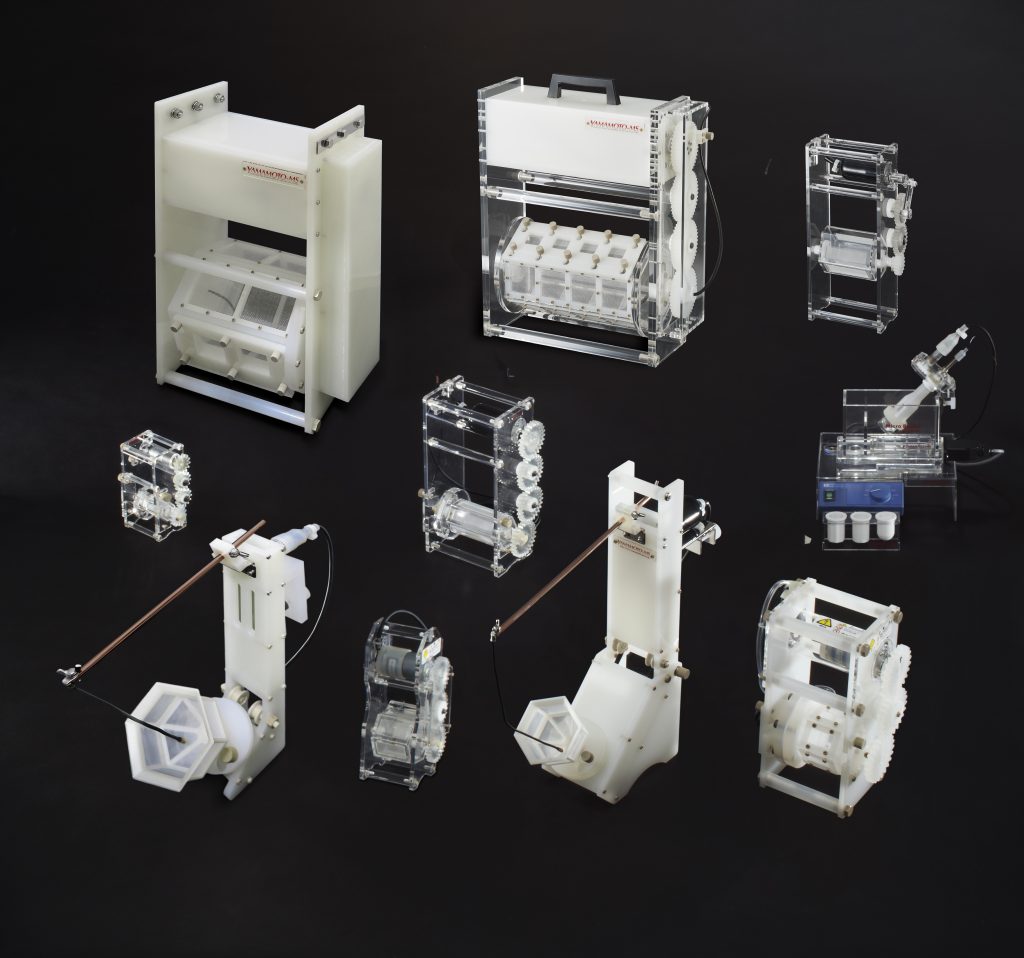

To plate on highly value-added micro parts, high-precision plating equipment is also essential. We focus on small desktop-sized barrels, and line up various items which meet customers’ requirements such as special processing which reduces samples get caught to drum’s inner side, designated drums to plate on ultra-fine parts, and so on.

Our barrel plating equipment is adopted by a lot of precision parts manufacturer. Parts plated by our barrel equipment may be found in your smartphones, cameras, watches, and other precision electronic devices.

What is Barrel Plating?

As the name implies, barrel plating is a device/method to plate on tons of plating samples uniformly by putting the samples into “barrel” shaped vessel and rotating it to mix samples. This method is suitable to plate on small and numerous items, and being adopted to plate on chip capacitors, accessories such as earrings, screws, washers, nuts, and so on. Normally barrel consists of frame and mesh to make plating solution and electricity pass through.

What is important for precision plating?

When plating on minute parts, it is said that more accurate plating can be achieved by preparing multiple small barrels and plating in parallel, rather than plating with one large barrel.

Barrel plating equipment can be roughly divided into “horizontal barrels” and “tapered barrels” according to the purpose.

Basically horizontal barrel is used, but for items that are difficult to plate with a horizontal barrel , an tapered barrel may be more effective. For details, please refer to the following technical information.

Difference between horizontal and tapered barrels

| Horizontal barrel | Tapered barrel | |||

|---|---|---|---|---|

| Features | Drum itself is closed with a lid. Drum attached horizontally. | Drum itself is not closed. Drum attached diagonally. |  |

|

| Pros/Suitable for | Samples are mixed well. Since it has a lid, samples cannot go out easily. Many samples can be put inside. |  | Since it has opening, Hydrogen gases generated during plating can go out easily.Suitable for very small powdery samples. |  |

| Cons/ Not suitable for | Hydrogen gases generated during plating tend to stay inside. | Mixing of samples is not good as horizontal barrel. Since it does not have a lid, need measure against sample leakage. |  |

|

Horizontal Barrel Lineup

Horizontal barrels are based on the “Mini Barrel” series, and include the “Tenori Barrel” with a drum capacity of 15mL for ultra-fine parts and the “Cradle Barrel” with a semi-rotational motion to reduce sample deformation.

Tenori Barerl

Cradle Barrel

Tapered barrel Lineup

Our tapered barrels lineups are “Shachihoko®” series with a wide variety of replacement drums and adjustable angles, the “Micro Barrel” with a porous drum, and barrels for aluminum plating that are special order.

“Shachihoko®”

“Micro Barrel”

aluminum plating barrel

Comparison Table of Barrel Plating Equipment

| Product No | Product Name | Type | Material | Drum Volume(*1) | Sample Volume(*1) | Opening(mm) | Max temp. | Input | Suitable tank |

|---|---|---|---|---|---|---|---|---|---|

| B-73-02AW | MINI BARREL FOR ELECTROLESS PLATING (drum type) | Horizontal | PP,etc | 145mL | 0.289 | 90℃ | AC100-240V | 5L Beaker | |

| B-73-03AW | MINI BARREL FOR ELECTROLESS PLATING (disk type) | Horizontal | PP,etc | - | - | - | 90℃ | AC100-240V | 5L Beaker |

| A-52-ST-EL | WAFER ELECTROLESS PLATING EQUIPMENT | Horizontal | PP/PTFE | - | - | - | 90℃ | AC100-240V | - |

| B-75BW | MINI BARREL MODEL 1-BW | Horizontal | Acryl,PP,etc | 140mL | 40mL | 0.105 / 0.289 / 0.44 / 0.97 | 65℃ | AC100-240V | B-89-CE-02T-PV B-76-KWMN-P03 |

| B-75CW | MINI BARREL MODEL1-CW | Horizontal | Acryl,PP,etc | 140mL | 40mL | 0.105 | 65℃ | AC100-240V | B-89-CE-02T-PV B-76-KWMN-P03 |

| B-76-03W | MINI BARREL100W | Horizontal | Acryl,PP,etc | 100mL | 30mL | 0.105 / 0.289 / 0.44 / 0.97 | 65℃ | AC100-240V | B-92-M10-P01 B-92-P01 |

| B-76-03AW | MINI BARREL 100AW | Horizontal | Acryl,PP,etc | 100mL | 30mL | 0.105 | 65℃ | AC100-240V | B-92-M10-P01 B-92-P01 |

| B-76-02AW | TENORI (hand palm-size) BARREL AW | Horizontal | Acryl,PP,etc | 15mL | 3mL | 0.105 | 65℃ | AC100-240V | B-89-CE-02T-PV 2L Beaker |

| B-73-1000 | Mini Barrel1000(1L-Type) | Horizontal | PP,etc | 2800mL | 1000mL | 0.97 | 90℃ | AC100V | B-92-P01 69 |

| B-75DW | Cradle Barrel | Horizontal | PP,etc | 240mL | 40mL | 0.105 | 65℃ | AC100-240V | - |

| B-74-M1AWJ-T04 | MICRO BARREL AND STIRRER SET(Pat.) | Tapered | Acryl,PP,etc | 15mL | 3mL | 10μm or Poreless | 65℃ | AC100-240V | B-74-M1-P02W |

| B-76-KWFN-W | Tapered Barrel Shachihoko | Tapered | PP,etc | 100mL | 20mL | 0.105 | 90℃ | AC100-240V | B-76-KWFN-P09A B-92-WF-PPM1-P01W B-92-P01 |

| B-76-KWFN-BW1 B-76-KWFN-BW-2 | Tapered Barrel Shachihoko Rugby-ball type | Tapered | Acryl,PP,etc | 290mL | 100mL | 0.105 | 65℃ | AC100-240V | B-76-KWFN-P09A B-92-WF-PPM1-P01W B-92-P01 |

| B-76-KWMN-W | Tapered Barrel Shachihoko Mini | Tapered | PP,etc | 100mL | 20mL | 0.105 | 65℃ | AC100-240V | B-76-KWMN-P07 3L Beaker (*2) |

(1) Volumes are for reference only.

(2) Not for use with rugby ball.

Drums

Mesh drums should be selected based on sample size and solution/gas release. Please click below for details on the standard lineup.

Dummy Ball

Dummy balls are used when there are not enough samples to be plated, or when items are sticking to each other. Please refer to the product page for selection points.

B-81 Dummy Ball

Special Order of Barrel Plating Equipment

We can provide the following custom-order services.

If you do not see the size you require, please contact us using the inquiry form.

■Example of specification change

- Change of drum mesh size ( mesh size: 0.113mm, 0.289mm, 0.44mm, 0.97mm, 0.105mm)

- Change of drum size, material, and shape (We have experience with drum capacities up to 3L)

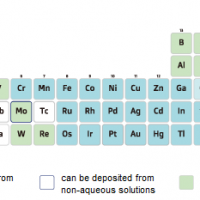

- Design and fabrication of barrels for special solutions such as ionic liquids

- Design and manufacture of barrels for aluminum plating