- Home

- Hull Cell, Technique

- Overview of Hull cell long type

TECHNICAL INFORMATION

Overview of Hull cell long type

Overview

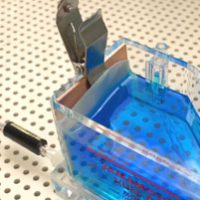

Hull cell long type is one of the types of Hull cells, and it enables to observe the deposition state in a continuous wide range of current density using a longer trapezoidal water tank. The liquid volume is about 430 ml, and the basic evaluation method is the same as for normal Hull cells. Please refer here for the test method of Hull cell.

History

The Hull Cell long type is a product that was devised by Mr. Murai of DIPSOL CHEMICALS Co., Ltd., and designed by us. It has been on sale since 2001.

At the beginning of the sale, YAMAMOTO-MS sold the type (A) that emphasized capacity, but “We should make it as dimensionally compatible with the standard Hull Cell as possible.” “We would like to show our respect to Hull Cell inventor Dr. Hull’s idea and to the DIN standard.” Based on those ideas, we have standardized the type (B) that emphasizes the distance between contacts.

A. Type that emphasizes capacity

It is a design that prioritizes that the amount of liquid in the water tank is 500 mL, which is nice round, and the plating area is 100 dm2, it also is nice round.

As a result, the top side of the trapezoid (shorter dimension 60 mm) and the height of the liquid surface (50 mm) are different from those of a normal Hull Cells.

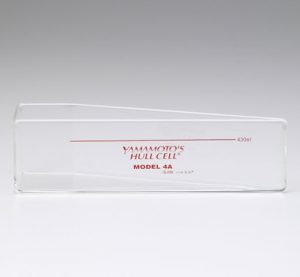

B. Type that emphasizes the distance between electrodes

The B type emphasizes the anode-cathode distance. It was designed with the aim of making the dimensions of the water tank as close as possible to a standard Hull Cell.

The upper side of the trapezoid (the shorter dimension is 48 mm) and the height of the liquid surface (46 mm) are the same as the normal Hull Cell. As a result of prioritizing the dimensions, the liquid volume is 430 mL.

Compliant with German standard DIN 50957-2

In June 2019, the Hull Cell long type was registered to DIN 50957-2 established by the German Standards Association.

In DIN 50957-2, “Testing of electrolytes used for electro-deposited metallic coatings – Test involving electro-deposition – Part 2: Special test cells)” is standardized.

What is the DIN standard?

Research Navi National Diet Library

“The DIN standard is a national standard of the Federal Republic of Germany established by the German Institute for Standardization (Deutsches Institut für Normung). It is a standard that is widely referred not only in Germany but also internationally.”

By registering the Hull Cell long type to the international DIN standard, it is possible to simplify the survey documents when introducing it as a plating solution management method. Moreover, since it is a standard that is widely referred to internationally as mentioned above, it can be expected that mutual understanding of management will be easier when dealing with overseas factories and companies.

Contribution to the standard

When the German Institute for Standardization focused on the usefulness of the Hull Cell long type and considered standardization, YAMAMOTO-MS received a request to make a demonstration tank and to provide document materials. It was because our sales achievement of Hull Cell for years, the accuracy of the product, and the validity of the cathode current density distribution formula proposed by us are highly evaluated. And we cooperated in standardization by exchanging various opinions, and it was adopted as DIN50957-2 by the standard revision in June 2019. (DIN 50957-2 Anhang B japanische Ausführung)

Features of Hull Cell Long Type

The Hull Cell long type is characterized in that the cathode is twice as long as normal Hull Cell, allowing you to observe a wider range of current densities. Suitable for evaluation of alloy plating and barrel plating.

Example of use in alloy plating

In alloy plating, the alloy ratio changes significantly at the current density depending on the bath composition. Therefore, it is necessary to evaluate at a finer current density. The Hull Cell long type, which allows observation of a wider range of current densities, has the advantage of making it easier to see low current density areas that are usually difficult to evaluate.

Example of use in barrel plating

Barrel plating has a wide range of current densities for one sample. This is because the object to be plated crawls inside the lump with the rotation of the barrel, and the current density becomes almost zero. In result of that, the change of cathode current density draws a huge Sine curve. Therefore, the Hull Cell long type is useful for confirming the film state (throwing power, etc.) in a wider current density range.

In barrel plating, however, different results may be seen from the static Hull Cell test, since the solution is agitated, and the samples contact each other and rub against each other. In addition, the influence of hydrogen overvoltage may occur. In barrel plating, the degree of plating deposition changes depending on the load volume of samples, but the condition can be kept constant by controlling the solution with the Hull Cell long type. Please use it for the maintenance of the plating solution by comparing the test result of Hull Cell Long Type and phenomena in the field relatively.

Product introduction

Tank

4 sorts of Hull Cell long type are available. You can choose appropriate type depending on the type of plating solution.

| Product name | Product No. | Appearance | Features |

|---|---|---|---|

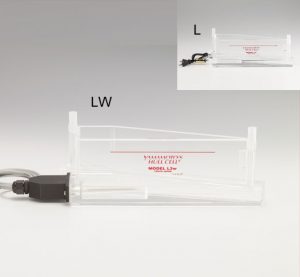

| Hull Cell (long type water tank long type) | B-55-L |  | Hull Cell using the longer cathode plate, without air agitation. The length of the cathode, 200mm, is twice that of the standard Hull Cell. Suitable for barrel plating, alloy plating and so on. |

| Hull Cell (Standard type water tank long type glass) | B-55-LG |  | Long-type Hull Cell made of glass, for use with thermostatic tank, for high temperature plating over 65℃ . |

| Hull Cell (Thermostatic-Control-Type/Long Tank) | B-53-L /B-53-LW |  | Hull Cell using longer a cathode, with air agitation. The length of the cathode, 200mm, is twice that of the standard Hull Cell. The long cathode plate makes it easier to observe the lower current area. Suitable for barrel plating, alloy plating and so on. B-53-LW is designed for the heater with built-in thermal fuse, and B-53-L is for the heater without thermal fuse. Heater is sold separately. |

| Hull Cell (Air-Agitation/Long-type Tank) | B-54-L /B-54-LW |  | Hull Cell using the longer cathode, with air agitation. The length of the cathode, 200mm, is twice that of the standard Hull Cell. The long cathode plate makes it easier to observe the lower current area. Suitable for barrel plating, alloy plating, and so on. |

Hull Cell Current-Density Scale(Long-Type)

Placing this scale on Long Hull Cell test piece, you can easily find current density without complicated calculations. For the calculation of current density, our original formula is used. (B-61-L: Japanese / B-61-L-E: English)

Related papers

Kimiko Koiwa, Wataru Yamamoto; Theory and Evaluation Example of Hull Cell Test Including for High Speed Platin, The Surface Finishing Society of Japan (2012)

* “Hull Cell” is a trademark registered product of YAMAMOTO-MS Co., Ltd.

Trademark registration No. 1294468 /Trademark registration No. 1278949 Some (R) marks are omitted in the text.