- Home

- Selection Guide

- Measuring Throwing Power

TECHNICAL INFORMATION

Measuring Throwing Power

What is throwing power?

To electroplate evenly on a sample with complicated shape, the condition which achieves uniform deposition in wide current density range is necessary. “Throwing power” is the property which indicates how evenly the plating bath is able to electroplate. Like current efficiency, it is influenced by variety of parameters such as composition of the bath, additives, temperature, current density, agitation, and so forth.

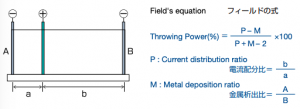

In general, the Haring cell is used in order to measure throwing power. By changing the position of an anode, current ratio to 2 cathodes varies. That means amount of deposition on the 2 cathodes are different, and by using the 2 different amounts of deposited metal and Field’s equation, throwing power can be calculated.

What is the Haring cell Test?

Haring Cell Test is a test to measure macro throwing power. Changing the position of the anode causes a change of the current distribution ratio, and consequently, a change weight ratio of the deposited metal on the two cathodes is also caused. Macro throwing Power can be obtained by substituting the values for Field’s Formula. To obtain uniform plated film on a work-piece with a complicated shape, it is necessary to arrange a condition, in which uniform thickness of the plated film is obtained over a wide range of current densities. The performance of the bath that enables such a condition is called macro throwing power.

Similar to current efficiency, macro throwing power is influenced by such factors as composition of the solution, additives, temperature, current density, and agitation.

The other usage of the Haring call

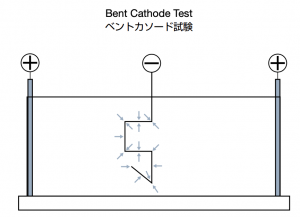

The Haring cell can measure not only throwing power, but also covering power. By using bent cathodes (sold separately), the Haring cell is able to measure the covering power of the plating bath.

And of course, the Haring cell is also able to be used as normal plating experiment tank.