TECHNICAL INFORMATION

Frequently Asked Questions about Wafer Plating Equipment

This page introduces frequently asked questions about our plating laboratory equipment for wafers.

About specifications

Q. What is the accuracy of YAMAMOTO-MS’s wafer plating device?

A. We have experimental results of film thickness distribution in 8-inch copper sulfate plating with less than ±3-5% variation in film thickness. For details of the experiments including plating conditions, please refer to the technical information here.

Results have also been published in a paper by our R&D partner, the Laboratory of Analysis and Architecture of Systems (LAAS).

David Bourrier, Arnaud Durlach. COMPARISON OF THICK COPPER PLATING RESULTS WITH LABORATORY AND INDUSTRIAL ELECTROPLATING TOOLS. Journées Nationales sur les Technologies Emergentes en micro-nanofabrication (JNTE 2017), Oct 2017, Orléans, France. 1p., 2017. ffhal-01873753f

Q. Can you process wafers with special shapes and materials?

A. Standard products are manufactured according to JEITA and SEMI standards, but we can also handle samples of various shapes, materials, and thicknesses as a special order. We have experience not only with round and square samples, but also with fan-shaped and semi-circular samples cut from round samples. A single jig can also process multiple samples.

Example of sample shape

Q. How do you make electrical contact with the cathode cartridge for wafer plating?

A. It depends on the type of jig, but standard products have electric contact points arranged on the circumference.

We can also make special-order types that have flat electrical contact points on the outer circumference or contact points on the backside.

If a sealed jig with sealing material is used, only the plated area can be plated.

Role of each device

Q. Can I use the wafer plating system without a mini-mini filter?

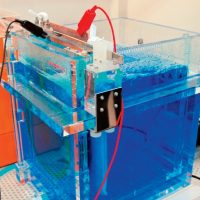

A. Our wafer plating system consists of an overflow agitator and jigs (cathode cartridge and anode holder).

We recommend using the mini-mini filter together with the overflow agitator since it has not only a filtration function but also a role in adjusting temperature distribution and concentration distribution.

Q. Can I use the wafer plating system without an anode holder?

A. No. The anode holder also functions as a shield* to improve film thickness distribution. It is necessary for precision plating.

*A shield is a non-conductive barrier to change the current distribution on the anode and cathode.

How to use

Q. Can I experiment with multiple wafer sizes in one plating tank?

A. Yes, as long as the wafer size is smaller than the tank standard. Please use a jig that matches the tank size. Samples larger than the tank standard cannot be plated because they will not fit in the tank.

Example 1) 4-inch sample can be plated in a 6-inch tank.

Example 2) 6-inch sample cannot be plated in a 4-inch tank.

Export

Q. Can the wafer plating system be exported?

A. Yes, we have exported our products to research institutes and manufacturers in various countries. For countries that require CE marking or other certification, the following measures are taken.

■Paddle agitator

Use models that conform to safety standards IEC61010-1 and EN61326-1.

A-52-ST-P04D Paddle agitator (DU/DW type, with built-in noise filter)

https://www.yamamoto-ms.co.jp/en/product/a-52-st-p04d/

■Liquid level sensor

Be sure to use the heater together with the liquid level sensor so that heating can be automatically stopped when the liquid level drops.

A-60 Liquid Level Sensor

https://www.yamamoto-ms.co.jp/en/product/a-60/