PLATING TESTER

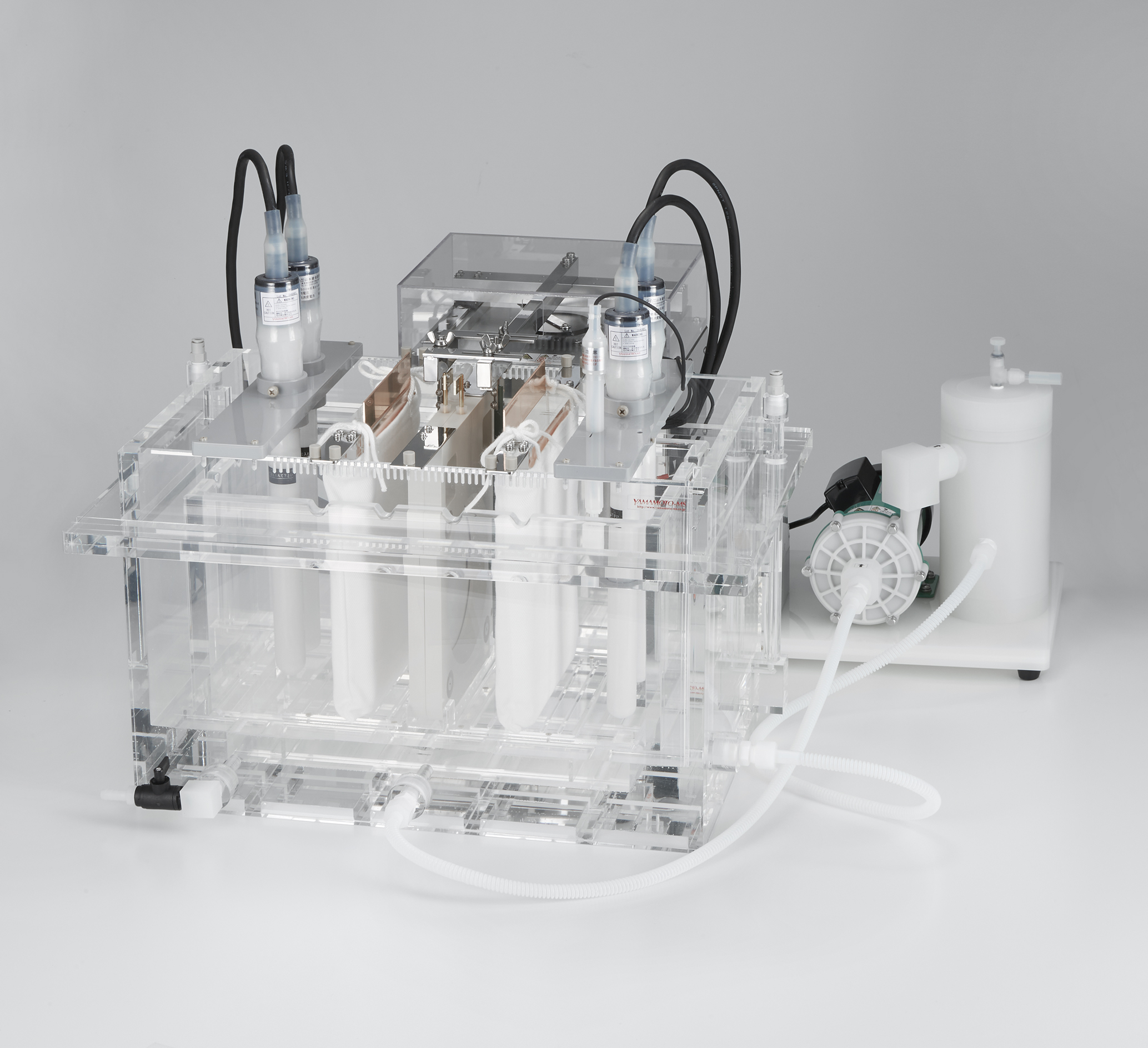

A-46WJ /A-46W AGITATION EFFECT TESTING KIT

This is a test device that plating a disk-type test piece (φ64xt03mm) while rotating it with a motor. The effect of agitation speed at a constant current density can be obtained on a single test piece. The effect of the additive on the agitation speed is noticeable.

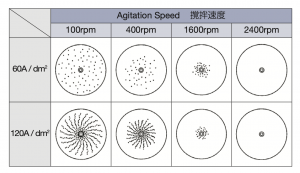

What you can see in the agitation effect test

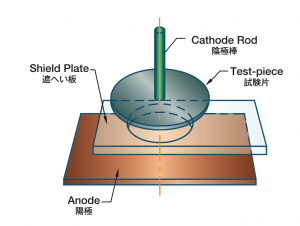

・Plating films with uniform current density, but varied agitation speed, can be obtained on a single test piece.

・Uniform current density distribution can be obtained by the use of a shield-plate (accessory).

・Agitation speed (peripheral speed) proportional to the diameter is generated on the test piece.

Usage Example

・For quality control of high-speed plating solutions

・For basic experiments of precise plating on silicon wafers

・For control of barrel plating and regular plating solution

By using it in combination with High Speed Plating Hull Cell , which can investigate the distribution of current density at a constant speed, more multifaceted analysis can be performed. Most of the parts are shared, so please use the set (A-45WJ-T) that can analyze both.

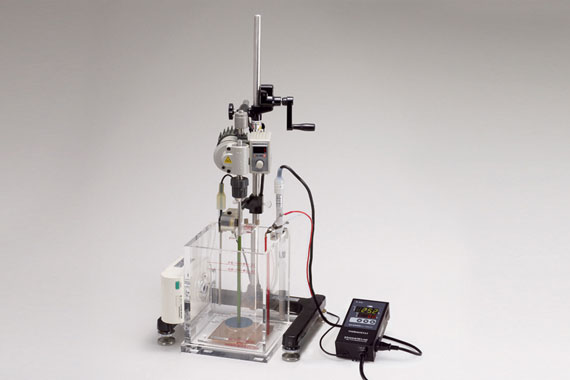

Specifications

| Outer (Installation) Dimensions | 325 (D)×305 (W)×730 (H) mm |

| Tank Volume | 5L |

| Main Unit Weight | 13.5kg |

| Rotator Capacity | 35W |

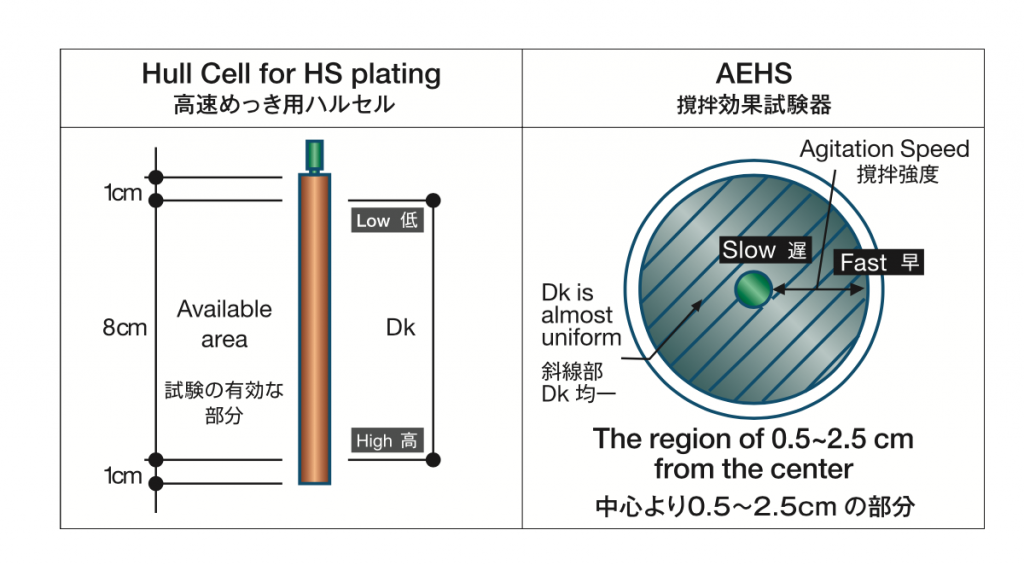

Principle of Agitation Effect Test for High Speed Plating ( AEHS )

Agitation Effect kit for High Speed Plating (AEHS kit) is the equipment needed to apply the Hull Cell Test for high Speed plating, HCHS. AEHS is the method for observing the plated results according to different agitation speeds with the same current density, while HCHS is the method for observing plated results according to different current densities with same agitation speed.

In AEHS, using the rotational disc cathode, both the low and high agitating speeds are achieved at the same time, on one cathode plate, with the same current density. By the effect of the shield plate, an almost uniform current density is achieved in the region of r = 0.5 ~ 2.5 cm, where r is the distance from the rotational axis. The diameter of the test piece is 64 mm, and the effective area to be plated is 0.31 dm2. The rear side of test piece is coated with insulating film.

[ Cathode current density distribution formula ]

Dk = a · I

Dk: cathode current density ( A/dm2 )

I: total current ( A )

a: constant determined by plating solution type and cathode current efficiency

valid in the region of r = 0.5 ~ 2.5 cm. ( r is distance from the rotational axis. )

[ Current density distribution in Ni plating solution ]

Dk = 2.11 × I

Structure of Agitation Effect kit for High Speed Plating

Example of Test Results in AEHS

Related Products

-

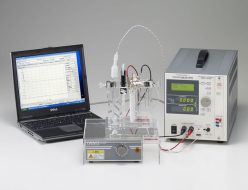

A-45WJ /A-45W HIGH SPEED PLATING HULL CELL TESTING KIT

A Hull cell teste that deposited film with a current density distribution for each stirring speed can be obtained on a single test piece. High-speed plating enables experiments with a current density closer to the actual site.

-

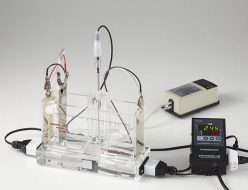

B-52-1CWJ HULL CELL TEST KIT MODEL-10A15

-

B-72WJ-SG STRAIN GAUGE TYPE STRESS METER

-

HULL CELL TEST KIT Model-YTC300 (B-52W-YTC300)

Hull Cell Test Kit that consist of Thermostat and Heater with built-in thermal fuse. This set is compliant with IEC standard and bears CE marking.

-

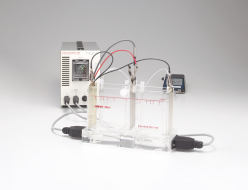

B-77WJ HARING CELL SET (Type WJ)

Haring Cell is used to identify macro throwing power of various plating solutions.

-

B-77W-YTC300 Haring Cell Macrothrowing Power Testing Kit YTC300

A set that combines CE marking with a temperature controller that supports AC100-230V voltage and a heater with a thermal fuse (DC48V).