WAFER PLATING

Micro Cell (Ⅰw) Silicon Wafer-use Set YTC300 A-53-*-ST01WB

Small acrylic-resin tank used for plating experiments. Designed to fit the heater into the base piece, making heating and air agitation possible.

Optimal for basic experiments for plating of silicon wafer chips and bump plating, etc. (M1:300mL , M2:500mL , M3:1000mL types) The jig for wafer chip plating is the standard equipment for the component set.

※ Tank Volume M1:300mL, M2:500mL, M3:1000mL

Set includes

(*example of Micro Cell IW set)

| A-53-M1-P01W-1 | Micro Cell (Ⅰw) Tank |

| A-53-M1-P05WA | Micro Cell Ⅰw /Ⅱw Heater w/Thermal Fuse (DC48V,50W) |

| B-93-YTC300 | Thermostat YTC300 (AC100-230V, 300W) |

| A-57-15030-P01 | Lead Wire (1-black/1-red, titanium clip) for Programmable Power Supply (3A) |

| A-55-PCR200BWA1 | Paddle Cathode Rocker 200BWA (with B-75-P16A Controller) |

| A-53-M1-P06-1015 | Micro CellⅠⅡⅢ Cathode Jig (for 10X15mm Test Pieces) Busbar not included |

| A-53-M1-P06-K1 | Micro Cell (Ⅰ) Cathode Jig (for 10×15mm Test Pieces) Busbar |

| A-53-M1-P07-1015 | Micro CellⅠⅡⅢ Anode Jig (for 10X15mm Test Pieces) Busbar not included |

| A-53-M1-P07-K1 | Micro Cell (Ⅰ) Anode Jig (for 10×15mm Test Pieces) Busbar |

*Anode plates are not included in the set and need to be ordered separately.

*Thermostat function/Lead Wire are included in your purchase of YPP-series Power Supply

*Refer to B-89-EP for Plating Solution

2020.05.01 Set contents changed. (Busbar, Holding Jig, Pinset are excluded)

Related Products

-

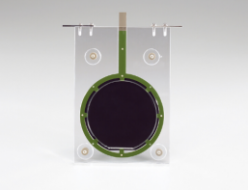

SILICON WAFER PLATING TANK (A-52-ST-P01A)

-

Silicon Wafer Cathode Cartridge(High current type)(A-52-STH*-P02A)

Silicon Wafer Cathode Cartridge(High current type)(A-52-STH*-P02A)

-

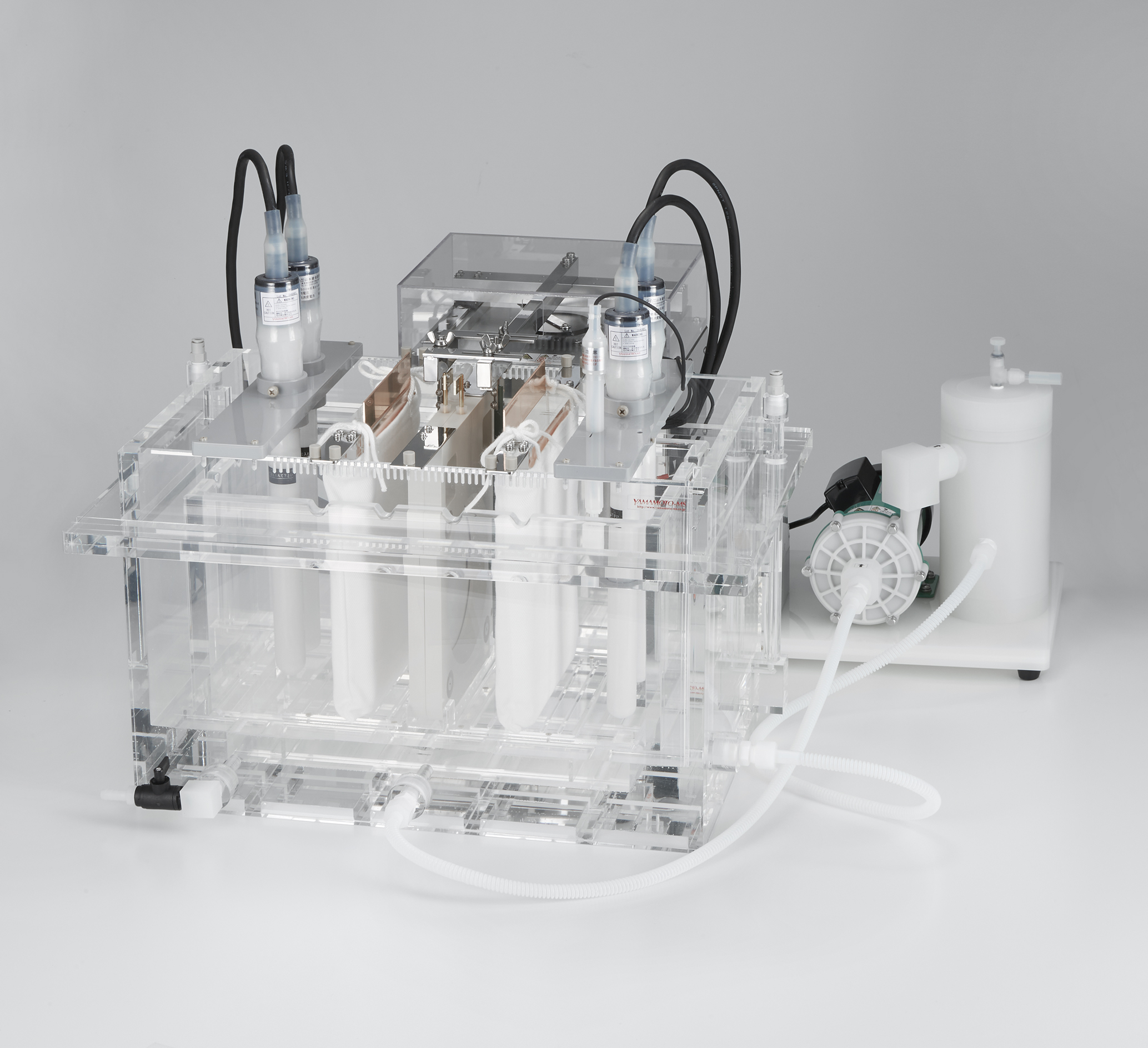

Smart Cell® (W) Silicon Wafer-use Set Assembly Example

A set of plating tanks ideal for basic experiments such as chip and bump plating of silicon wafers. Stable current distribution is realized by using overflow circulation.

-

Wafer Anode Holder

-

Silicon Wafer Cathode Cartridge

-

Smart Cell ®(Model-500G)(A-56-0500G)

It is a glass tank type of the smart cell series that overflow circulates using a magnetic stirrer without using pumps. Fluctuations in the liquid level due to evaporation, etc., can be suppressed by overflow stirring, and stable current distribution and plating area can be maintained.